Metallurgical Contract Research & Development

and

Advanced Casting Solutions

MHD Research Centre is a research institute that draws on results of more than 20 years of scientific and applied research of the University of Latvia and its’ partners in metallurgical field, primarily, magnetohydrodynamics in metal casting.

The Centre was founded in 2011 by the University of Latvia and private partner Dilers Metals Ltd as a spin-off company with an aim to commercialize scientific research developments. Role of the Center is to realize the proof of concept - demonstration of new and disruptive innovations at the actual scale in industrial conditions.

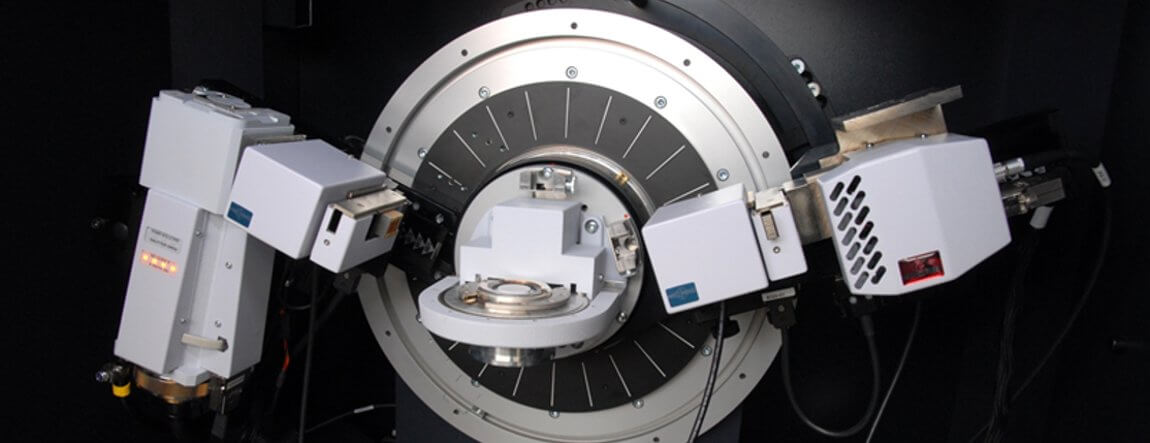

Our personnel and infrastructure enables unique focused opportunities for cooperation. The Centre possesses an 20 metric ton melting furnace configured for research and demonstration of full production process, including degasser, filters and billet casting unit all designed and accustomed for modification and scientific and applied research purposes by addition of observation windows, exchangeable electromagnetic pumps, temperature & pressure measurements, and other components necessary for agile investigation of real scale production process.

The Centre is registered in the Register of Scientific Institutions of the Republic of Latvia and provides contract research and development and industrial demonstration services in the following primary areas: electromagnetic processing of materials, magnetohydrodynamics, flow control (EM pumps, mixers, dozers, brakes), process metallurgy, casting technologies for light metal industries, suppliers and related parties, and recovery of metals from electronic waste. The Centre’s laboratory also has a full set of advanced analytical equipment for testing of metal sample composition, structure, temperature distribution, and other parameters and factors.

The Centre as has developed and set up as industrial demonstrator a Permanent magnet based electromagnetic pump and stirrer for aluminium remelting industry. It is set up as 20t aluminium furnace side stirrer, but concept works also as bottom stirrer, rectangular channel pump and aluminium dispenser. It has been demonstrated that developed concept works with also with thick walls (up to 20 cm as pump and 50cm as stirrer), providing energy consumption reduction 5-10 times (!) at about 20 - 60% smaller cost compared to conventional AC inductors. Precise achievable parameters and prices will be provided upon quotations. Demonstration of industrial prototype on 20t furnace can be organized by request.

Currently The Centre is conducting development work on following projects:

- Use of non-contact induced ultrasound for improving crystallization structure and dispersion of micro and nano particles in melts.

- Permanent magnet based electromagnetic stirrer for improving crystallization structure during steel slab and strip casting.

- Contactless Aluminium channel flow meter.

- Single stage Ferrotitan production technology of directly from Rutile.

Please keep updated of potentially very interesting results in our dedicated web site mhdresearchcentre.com

We are ready for wide range collaboration, including research,

commercialization and application of developed technologies,

and joint research preparation.